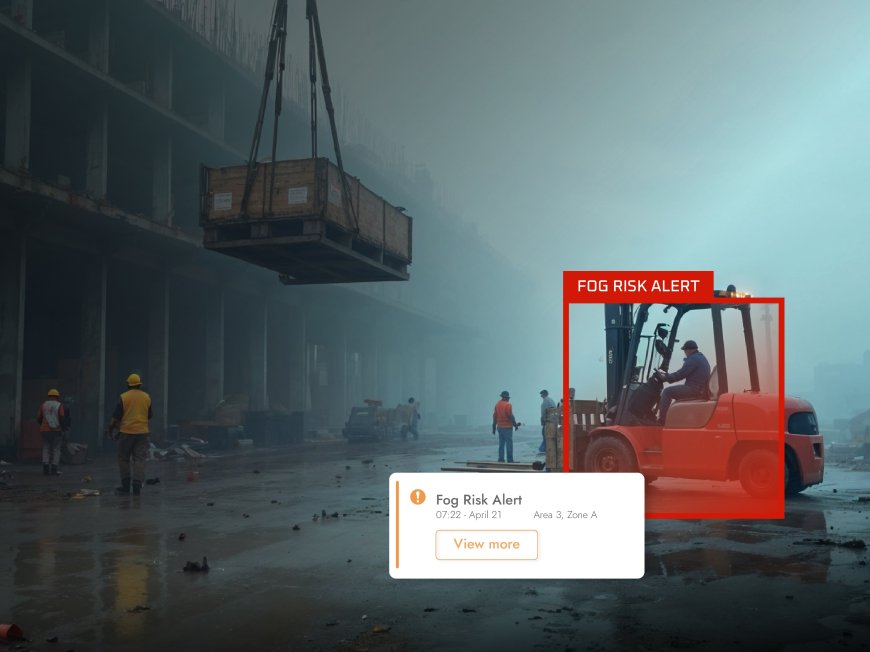

Can AI Cut Workplace Incidents and Improve Output? The Data Says Yes

When it comes to AI in the workplace, most conversations still circle automation, robotics, or fears of job loss. But something quietly revolutionary is happening in the high-risk industries — and the numbers are hard to ignore.

When it comes to AI in the workplace, most conversations still circle automation, robotics, or fears of job loss. But something quietly revolutionary is happening in the high-risk industries — and the numbers are hard to ignore.

Workplace safety is improving. So is output. And the common factor? AI.

According to a study by Deloitte, 60% of business owners believe AI significantly boosts productivity, while 42% agree it helps streamline job processes, making operations more efficient and focused.

But how does the balance work?

Let’s dig deeper and see what the data says.

1. Confined Space Monitoring: 85% Faster Incident Reporting

In multiple large-scale projects across sectors like oil & gas, mining, or construction, incorporating an AI-powered Confined Space Monitoring using edge AI devices for on-the-source reporting reduces the time-to-report for safety incidents by 85% — thanks to real-time alerts that reach site supervisors instantly.

The output here was in the form of projects attaining 30% less unplanned downtime, as crews didn’t have to halt work for manual inspections or investigations.

2. Fire & Smoke Detection: Zero False Alarms, Real-Time Response

After installing a Vision AI-based fire detection system, one offshore client reported zero false fire alarms in 3 months, with detection speeds under 3 seconds. Apart from that fugitive emissions that often halt operations when go unnoticed in their initial phases saw a sharp decline.

The output secured operations with uninterrupted workflow. Workers focused on task — not on false evacuations or system resets.

3. Fleet Management Tracking: 21% Improvement in Timelines

On a tunneling project in Southeast Asia, deployed an AI-powered Fleet Management System that helped project managers predict delays and reallocate resources proactively. With automated route optimization facilities and 24/7 visibility with GPS tracking, the idling hours and poor driving habits can be noted.

The output showcased project timelines improved by 21%, and daily reporting time dropped by over 70%.

“It’s not just about safety events anymore, It’s about continuous visibility — the kind that drives real business results,” says Hugo Cheuk, COO & Co-founder of viAct.

4. Behaviour Based Safety System: 90% Injury Reduction

By combining Computer Vision with a behaviour based safety system, an early intervention on unsafe worker behaviour such as running or jumping, unauthorized grouping, leaning over machinery, skipping designated pedestrian pathways, or smoking in hazardous areas thereby reducing the total recordable incident rate (TRIR).

The output indicated up to 90% reduction in workplace injuries, which directly led to lower insurance claims and increased site uptime.

5. Conversational AI paired with Job Hazard Analysis (JHA): 75% Reduction in Safety Reporting Time

Integration of conversational AI chatbots like viGent with Job Hazard Analysis Software helps in safety instrumented function (SIF) with digitized safety checklists, guiding the teams before every specific task.

With pre-built JHA templates, teams can quickly break down tasks, assess risks, assign severity levels, and instantly access updated SOPs all through a conversational interface.

Real-time risk identification, predictive maintenance of equipment and vehicles, incident logging, and hazard trend detection are streamlined with Generative AI, minimizing manual inputs and human error.

The output resulted in safety teams 75% reduction in reporting time, freeing them to focus on real-time supervision, faster decision-making, and proactive risk control, all while keeping operations compliant, standardized, and productive.

Conclusion: The Safer the Site, the Smarter the Output

From confined spaces to control rooms, AI is proving to be more than just a safety net, it’s becoming a strategic enabler of operational excellence. The data points in one direction: fewer incidents, faster reporting, smarter decisions — and ultimately, better business outcomes.

And this shift isn't happening in silos. From AI video analytics and behaviour based monitoring to Conversational AI and Job Hazard Analysis, technologies once considered futuristic are now the foundation of day-to-day operations across high-risk industries.

Gary Ng, CEO of viAct, rightly points out - “Safety doesn’t have to slow down progress when AI systems are designed to learn from risks, they empower teams to build faster, work smarter, and prevent problems before they ever occur”.

The bottom line?

AI is not replacing humans — it's elevating their roles, improving site visibility, and ensuring every safety measure contributes directly to productivity.

So, can AI cut incidents and improve output?

The data doesn’t just say yes — it proves it.