How Wrangler created affordable “circular” jeans for Walmart

Although limited in scope, the Kontoor subsidiary's effort offers valuable lessons for sustainability professionals The post How Wrangler created affordable “circular” jeans for Walmart appeared first on Trellis.

Key takeaways:

- The pants stand out for their low price point and high percentage of recycled material.

- Brands, yarn and fabric makers, working with nonprofit Accelerating Circularity, collaborated to build a circular production system.

- The effort demonstrated that blending fiber from secondhand clothes with virgin cotton is technically feasible for denim at scale.

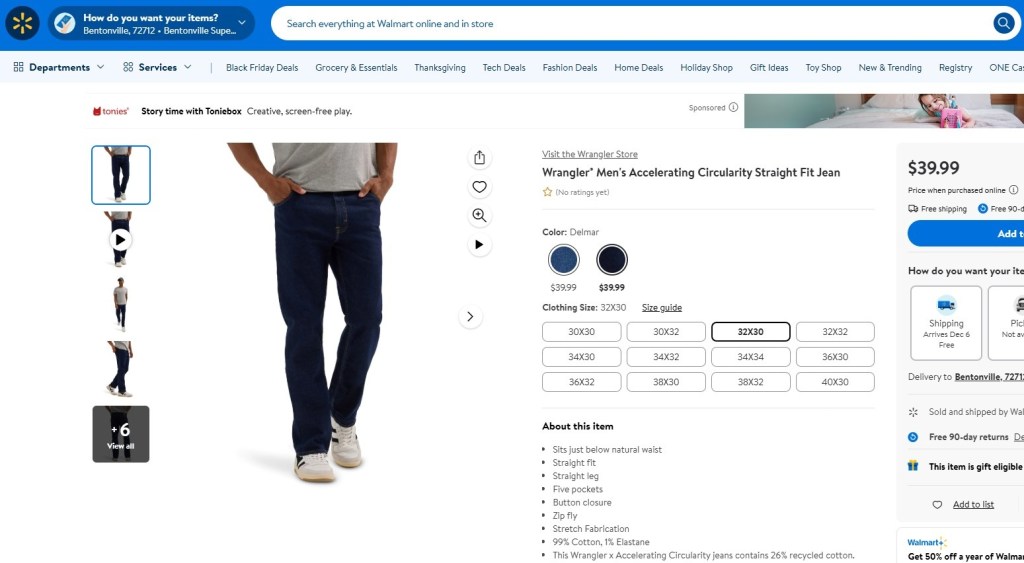

Wrangler’s latest jeans for Walmart are the first relatively inexpensive fashion product to feature a significant amount of recycled cotton from used clothes. The dark men’s jeans, which are also recyclable, debuted on March 7 and were the result of a collaboration with waste collectors, yarn spinners and denim makers to scratch-build a circular manufacturing system.

The $39.99 Accelerating Circularity jeans contain 26 percent recycled cotton, half from pre-owned garments and half from factory discards.

“That is the thing, that it can go to the mass market level,” said Dhruv Agarwal, vice president of innovation and research and development at Wrangler’s parent company, Kontoor Brands. “That is the signal we are sending — that we can do it.”

The jeans are double the price of other Wranglers at Walmart but remain less costly than others with recycled fibers. For example, in 2022 Levi’s Circular 501 jeans, costing more than $100 each, blended recycled Circulose material from waste textiles with organic cotton.

Although Wrangler made fewer than 2,000 of the new jeans for online sales only, circularity advocates see them as a sign of things to come.

“Wrangler’s Accelerating Circularity jean stands out by utilizing pre-existing waste, effectively giving materials a second life,” said Chana Rosenthal, founder of reDesign consulting in New York City and a former Ralph Lauren denim design director.

“This is a hero story,” said Lauren Fay, founder of the Seattle fashion sustainability consultancy BFG Lab. “I hope that Walmart and Wrangler have aggressive plans to scale this model that is not connected to the ROI on the jeans project,”

The effort is Kontoor Brands’ latest experiment to diversify sourcing and therefore reduce dependence on natural resources, including virgin cotton and water, according to Agarwal. However, further mainstreaming circular fashion requires driving down the costs of materials and processes that treat waste as a resource — which policies and advances in chemical recycling could accelerate, he added.

“You cannot just achieve 100 percent recycled; you basically start somewhere,” Agarwal said. “You need to see the economies of scale. You need to see the quality of the product. It’s a dynamic, continuous improvement process.”

Kontoor’s climate targets

Kontoor, which was spun off from VF Corporation in 2019, is based in Greensboro, North Carolina, where Wrangler jeans emerged in the late 1940s as a favorite among rodeo cowboys. Kontoor also runs the 136-year-old Lee and 3-year-old Rock & Republic denim brands.

Using more recycled materials is a small but important component of the corporation’s goal, approved by the Science Based Targets initiative, to shrink emissions by 46.2 percent by 2030 across Scopes 1, 2 and 3 over a 2019 baseline, according to Agarwal.

The company is developing a strategy for “circular pathways” of recycling, resale, upcycling, reuse and repair, according to Agarwal. Designing durable garments with circularity principles is another element. Among Kontoor’s other attempts to advance circularity:

- In 2023, a Circularity Working Group at Kontoor began embedding circular principles into product design standards. Designers and product developers also work together with procurement and sustainability staff to incorporate circular principles into garments.

- By 2023, Kontoor’s sourcing had reached 74 percent “preferred cotton,” which includes verified recycled cotton, toward a target of 100 percent for 2025.

- In 2022 and 2024, Kontoor sold Wrangler Reborn vintage and upcycled denim designs dating back to the 1950s.

- Kontoor participated in the Jeans ReDesign project of the Ellen MacArthur Foundation, which from 2019 to 2023 engaged scores of brands to design jeans for circularity.

- Wrangler’s fall 2021 collection involved an early foray into chemical recycling that used “regenerated fiber” from Finnish company Infinited Fiber.

How to build a circular system

Kontoor has worked for several years with the nonprofit Accelerating Circularity, which led the partnership to craft the five-pocket Wrangler jeans. Creating a circular production system departed from the typical linear processes of growing a crop, then creating fibers, fabric and a garment that eventually gets thrown away. “We’re making a transformation, and transformation is hard,” said Karla Magruder, founder of Accelerating Circularity.

That effort engaged companies across the apparel value chain. Together, the partners determined how to ensure that the final garment could be recycled, by blending 99 percent cotton with only 1 percent elastane. They settled on mix of mostly virgin cotton, plus waste split between factory clippings and pre-worn “post-consumer” knits, Magruder said.

Magruder likened the process of sourcing waste material — from South America, India and the U.S. — to growing and harvesting a crop for fiber. “This is our feedstock,” she said. “But this isn’t a commodity yet, so we’re having to gather it from scratch and then pre-process it.”

Secondhand clothing trader Bank & Vogue collected used clothes, and Martex gathered the production scrap. Tons of the material was then shipped to Giotex and Estopas, which shredded and recycled it into rough fibers. After that, yarn manufacturer Parkdale Mills spun both the recycled fibers and the virgin cotton into yarn. Cone Denim wove that into denim on production-scale equipment, according to Magruder. Wrangler’s cutting and sewing happened in Mexico.

Accelerating Circularity’s North American pilot projects have recycled 23 metric tons of waste cotton. The organization plans to recycle another 325 metric tons under its commitment to the Clinton Global Initiative Commitment to Action.

What sustainability pros can learn from this project

For Agarwal, working intimately with partners across the value chain illuminated the power of collaboration to change entrenched systems.

That’s important, because the apparel industry struggles with scaling circular production partly because the business case is unclear, according to consultant Rosenthal. “Wrangler’s successful partnership model provides a blueprint for overcoming these obstacles, proving it can be done. But we need robust financial analysis that demonstrates the economic benefits for industry-wide replication.”

Says Magruder: “I want the people who are making products to take something away from this. The sustainability people believe in this already.”

The post How Wrangler created affordable “circular” jeans for Walmart appeared first on Trellis.

![The breaking news round-up: Decagear launches today, Pimax announces new headsets, and more! [APRIL FOOL’S]](https://i0.wp.com/skarredghost.com/wp-content/uploads/2025/03/lawk_glasses_handson.jpg?fit=1366%2C1025&ssl=1)