Inside Amazon’s blueprint for cutting building emissions

The company is switching to lower-carbon construction materials, prioritizing natural refrigerants and using AI to fine-tune energy and water consumption, for starters. The post Inside Amazon’s blueprint for cutting building emissions appeared first on Trellis.

Key takeaways

- Amazon is kickstarting low-carbon concrete and steel startups with investments from its $2 billion Climate Pledge Fund.

- The company uses five principles to drive building management decisions but tailors them to region and facility type.

- One potential blocker: Technicians trained to fine-tune new equipment and artificial intelligence tools.

Amazon manages thousands of facilities across 20 different building types — from data centers to commercial offices to grocery stores to distribution centers.

The company is countering their greenhouse gas emissions by switching to mass timber, lower-carbon concrete and steel for construction; replacing refrigerants with high global warming potential; and using artificial intelligence to fine-tune energy and water consumption, to name a few best practices.

Amazon doesn’t disclose exactly how real estate contributes to its carbon footprint, but in general buildings account for close to 40 percent of the world’s carbon footprint.

“In an average building, we like to think of it as half the emissions are in the materials themselves — in the embodied carbon as part of construction — and the other half are in the operational emissions from operating with utilities and refrigerants,” said Chris Roe, director of worldwide environment, carbon, at Amazon.

Purchases that cut construction emissions

Amazon is investing to reduce emissions across both phases of a building’s life. Its $2 billion Climate Pledge Fund has backed Brimstone Energy and Paebbl, two early-stage startups focused on reducing emissions from supplementary cementitious materials; CarbonCure, which injects carbon dioxide in fresh concrete to sequester it; and green steel maker Electra, to name a few.

Amazon is also changing its purchasing habits to favor these disruptive technologies. Amazon’s east coast headquarters, for example, features 70-foot-long mass timber beams, a layered alternative to steel beams, and low-carbon concrete. The headquarters uses 24 percent less energy than similar complexes; the concrete portions of the campus have a carbon footprint that is 20 percent lower than traditional approaches.

Looking ahead, Amazon has decreed all new data centers be constructed with 35 percent less embodied carbon than construction as usual. In 2023, 29 Amazon building projects sourced lower-carbon materials, cutting 79,500 metric tons of CO2 equivalent, or the annual emissions of 17,200 cars. As of January, these materials were used in 40 buildings.

“We’re looking at ways that we can send demand signals to bend cost curves for everyone,” Roe said. “These are hard problems that no one company wants to solve alone.”

Amazon sets goals for embodied carbon for each construction project, and at the close it collaborates with contractors to calculate the footprint for all materials, using resources such as the free EC3 accounting tool from nonprofit Building Transparency.

“They ask the harder questions about the impact they are trying to have rather than just using proxy labels and oversimplified metrics,” said Lindsay Baker, CEO of the International Living Future Institute, a nonprofit that advocates for carbon-free building design. “Their standards of how they build are more carefully written to focus on measurable carbon impacts.”

Several Amazon buildings are certified under the institute’s zero-carbon methodology, including Amazon’s same-day delivery center in Sacramento, California — the first North American fulfillment facility to earn this designation.

Features that helped earn that recognition include the parking lot, made of locally sourced and repurposed materials; low-carbon concrete for the floors that cut embodied emissions by 33 percent; and material handlers with high-efficiency motors and low-friction belts and rollers that reduce energy consumption 38 percent compared with similar equipment.

Achieving these sorts of outcomes requires close partnership with construction firms, real estate investors and building management companies. “We’ve been using these kinds of mechanisms and really key partners across real estate to work together on this,” Roe said. “I would absolutely underscore that point.”

AI for better management and maintenance

To address operational emissions, Amazon developed a suite of software applications to reduce energy and water consumption. They include:

- FlowMS, which detects water leaks that aren’t visible to the human eye. At one location, it prevented the loss of more than 9 million gallons annually.

- Base Building Advanced Monitoring, which picks up malfunctions in heating, ventilation and air-conditioning systems that are a drag on energy efficiency. It will be deployed at more than 300 buildings by the end of 2025.

- Advanced Refrigeration Monitoring, which analyzes equipment that keeps perishable goods at optimal temperatures across Amazon’s grocery network in North America and Europe. In one location, the software flagged a faulty defrost cycle, preventing food loss and saving 1,000 hours in equipment downtime.

Key team priorities, regardless of building type

Amazon’s real estate team uses five core principles to guide emissions reductions and other sustainability decisions for building selection, construction and operations.

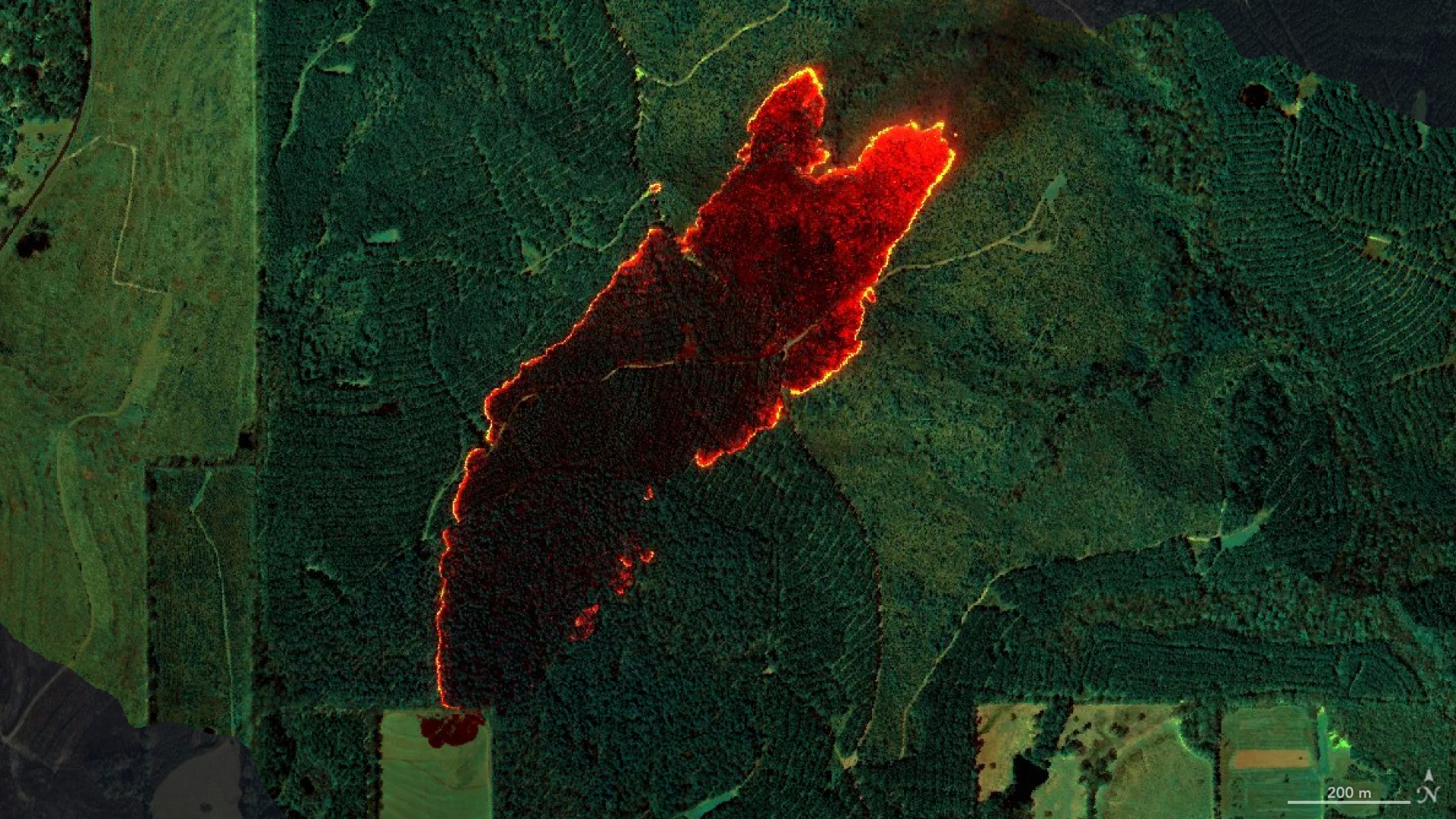

- Prioritize sites with access to carbon-free energy: Amazon hosts more than 300 on-site solar installations in the U.S., Europe and Asia. Some can handle 80 percent of a site’s energy needs. Amazon matches electricity with power purchase agreements to claim reductions: it’s the largest corporate renewables buyer at more than 600 projects.

- Source lower-carbon building materials when and where possible: These replacements can be simple. Amazon’s delivery center in Sacramento, for example, opted for plywood decking on its roof, which reduced the embodied emissions of that feature by 49 percent compared with steel.

- Increase energy efficiency: More than 200 “boots on the ground” audits were conducted in 2024; the findings will inform future retrofits or fixes that are straightforward, such as installing air curtains on a distribution center’s loading dock doors to keep conditioned air inside.

- Reduce on-site water consumption: Conservation and stormwater management are table stakes for all sites. Some managers are experimenting with newer approaches, such as atmospheric water harvesting, which Amazon uses at commercial offices in India to collect evaporation.

- Opt for natural refrigerants: This is a requirement for new Amazon Fresh and Whole Foods sites that’s likely to find its way into other types of facilities.

“The implementation of how we’re going to be able to roll out the sustainability-focused practices is going to depend on several factors: local regulation, where we are in terms of geography across the portfolio is going to drive how we have to tailor to each of the facilities,” said London Kemp Boykin, director of worldwide real estate development at Amazon. “But we do have standards that are embedded across all of the design and engineering work streams within the operations verticals. Most buildings are going to incorporate some portion of those standards.”

Spotlight on refrigeration

At new Amazon Fresh and Whole Foods grocery stores, for example, Amazon is installing refrigerants made of ammonia, CO2, propane and other naturally occurring gases rather than synthetic ones carrying a higher global warming potential.

“So much of our modern lives revolve around refrigeration,” said Danielle Wright, executive director of the North American Sustainable Refrigeration Council, an industry group that advocates for these technologies. “This is a big opportunity that could have a big impact today. You can think of this as buying time.”

The 35,000-square-foot Amazon Fresh in Seattle saved at least 100 metric tons of CO2 equipment compared with similar stores by opting for these refrigerants, along with all-electric kitchen equipment and hot water.

Refrigerants accounted for a small fraction of Amazon’s Scope 1 emissions in its 2023 environmental report. That impact has grown since Amazon’s 2019 baseline year, but it shrank 25 percent between 2022 and 2023 thanks, in part, to the grocery switchover.

Amazon is applying lessons learned from this transition to other facilities, including data centers. One thing holding the company back is the low availability of local technicians trained to maintain these systems, so Amazon is investing in training to scale that workforce amid a shortage of HVAC specialists.

“If we don’t have people, technicians to install and maintain, then no one will realize this transition,” Wright said.

The post Inside Amazon’s blueprint for cutting building emissions appeared first on Trellis.