Progress report: Apple’s push to use recycled aluminum, rare earths and 13 other materials

The company avoided 6.2 million metric tons of emissions in 2024 by opting for recycled and low-carbon materials, according to its 2025 Environmental Progress Report. The post Progress report: Apple’s push to use recycled aluminum, rare earths and 13 other materials appeared first on Trellis.

Key takeaways

- A transition to recycled sources also pays off in emissions reductions.

- Recycled content represented 24 percent of the materials (by mass) in products shipped to customers in 2024.

- Barriers to recycled content include trade treaties, limited origin data and scarce supply chain capacity.

Apple’s push to source 15 priority materials entirely from recycled or renewable sources — including aluminum, rare earths and lithium — is paying off in appreciable emissions reductions for its manufacturing processes.

Apple has reduced its greenhouse gas emissions by 60 percent since 2015, on its way to a 75 percent cut by 2030, according to the 2025 Apple Environmental Progress Report published April 16. (Emissions were 15.1 million metric tons, down from 22.6 million in the baseline year.) During the period in question, Apple’s revenue grew 65 percent, to $391 billion.

Much of Apple’s reported reduction came from renewable electricity investments, but sourcing recycled and other lower-carbon materials helped the company avoid 6.2 million metric tons of emissions in 2024. Avoided emissions, sometimes called Scope 4, are calculated by estimating the amount of greenhouse gases that weren’t emitted because of production changes or other measures and subtracting them from historical emissions trends.

Apple claimed 41 million metric tons in avoided emissions for 2024. Moving to recycled materials accounted for 15 percent of that claimed reduction. For context, product manufacturing activities represent 54 percent of Apple’s overall carbon footprint.

Recycled content from sources certified to ISO 14021 specifications accounted for 24 percent of the materials in Apple products in 2024. The product containing the most recycled materials was the MacBook Air, at 55 percent. A close second is the latest Mac mini: 50 percent of its components come from recycled sources and it is manufactured using renewable energy, making its footprint 80 percent smaller than a mini created using a business-as-usual scenario, Apple said.

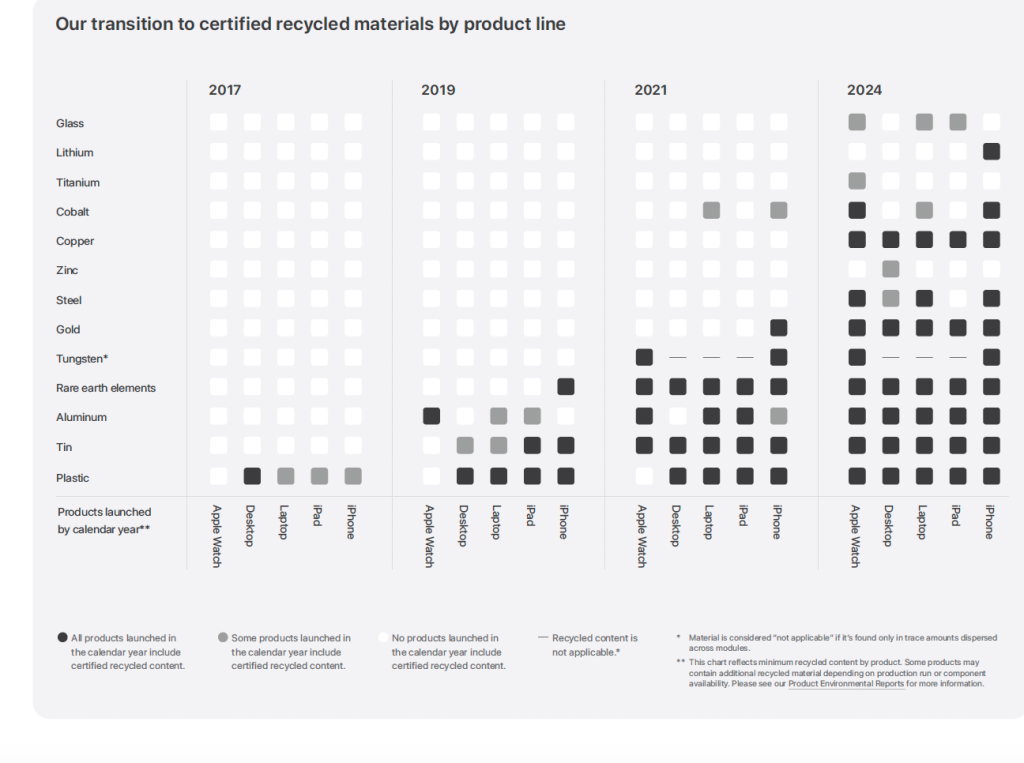

The company is prioritizing 15 materials in its recycled content transition, representing 87 percent of its production by mass: aluminum, cobalt, copper, glass, gold, lithium, paper, plastics, rare earth elements, steel, tantalum, tin, titanium, tungsten and zinc.

“Our strategy is to transition to materials that are manufactured using low-carbon energy and recycled content,” the company said in its environmental report. “We’ve prioritized the materials and components that make up a large part of our product carbon footprint to move us closer to our goal of carbon neutrality.”

Spotlight on aluminum

Case in point: Apple used recycled sources for 71 percent of the aluminum it bought in 2024 — a strategy that could prove prescient as manufacturers reckon with Trump-era aluminum tariffs.

Recycled aluminum is used for the enclosures of pretty much every Apple product: the latest Apple Watch series and Mac mini models, MacBook Air and MacBook Pro, iPads and iPhones. Apple reclaims a portion of that aluminum from old Apple products that it takes back through trade-in programs and procures the rest from other post-consumer and post-industrial sources.

That initiative has reduced aluminum-related emissions 76 percent since 2015. The material represented 7 percent of Apple’s product manufacturing footprint for 2024, compared with 27 percent in the baseline year.

Apple is also investing in a Canadian venture, called Elysis, commercializing a process to smelt aluminum without emitting direct greenhouse gases. The material isn’t yet available at industrial scale, but it’s been used in some iPhone SE models, circa 2022.

Work in progress

Apple has several other near-term goals for recycled metals and rare earth elements that it’s close to meeting. They include:

- Recycled cobalt for all Apple-designed batteries: It’s at 99 percent for the batteries; 78 percent of the cobalt sourced for all products in 2024 was recycled, compared with 52 percent in 2023.

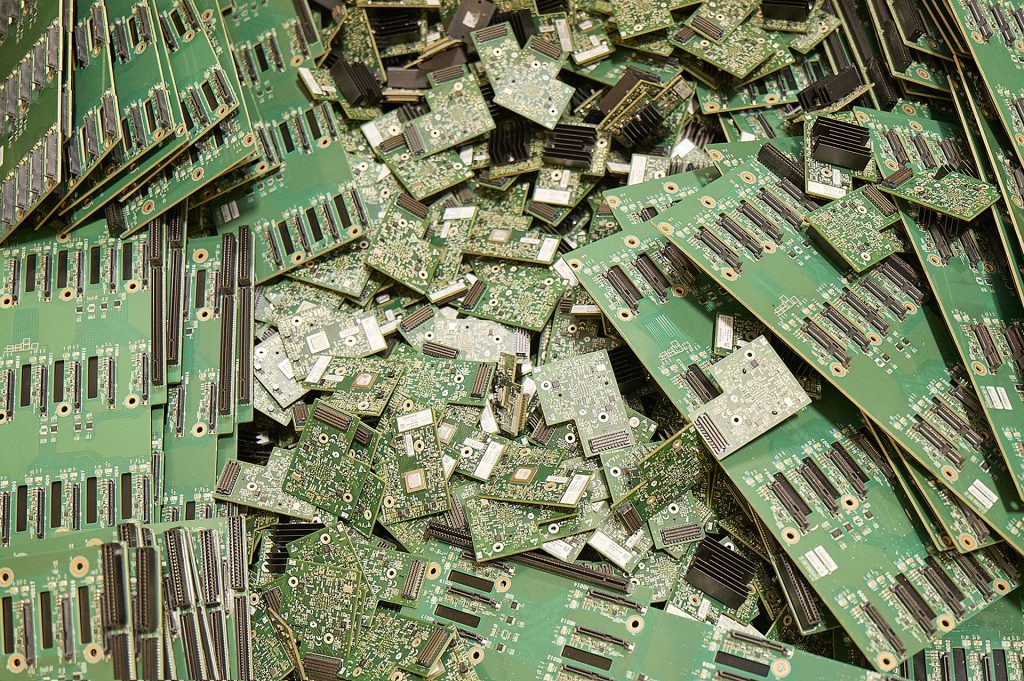

- Recycled sources for all tin soldering and gold plating in certain circuit boards: They represented 99 percent in 2024.

- Recycled rare earth elements for all magnets: They represent 99 percent of what’s used in Apple batteries and 80 percent for all of Apple’s rare earth needs.

In addition, Apple’s progress on sourcing recycled gold — used in circuit boards, connectors and chips — accelerated from 2021 to 2024. In 2024, recycled gold was used for 40 percent of material in all products, up from 1 percent in 2021. The company doubled the number of suppliers certified to manufacture these materials over the past 12 months.

Challenges to future increases in recycled materials usage include overcoming technical concerns such as durability and potential contamination; constrained supply availability; limited data that traces origins; and international regulations that may inhibit cross-border shipments. “Addressing these takes a collective response,” Apple said.

The post Progress report: Apple’s push to use recycled aluminum, rare earths and 13 other materials appeared first on Trellis.

![The breaking news round-up: Decagear launches today, Pimax announces new headsets, and more! [APRIL FOOL’S]](https://i0.wp.com/skarredghost.com/wp-content/uploads/2025/03/lawk_glasses_handson.jpg?fit=1366%2C1025&ssl=1)