NASA Enables Construction Technology for Moon and Mars Exploration

One of the keys to a sustainable human presence on distant worlds is using local, or in-situ, resources which includes building materials for infrastructure such as habitats, radiation shielding, roads, and rocket launch and landing pads. NASA’s Space Technology Mission Directorate is leveraging its portfolio of programs and industry opportunities to develop in-situ, resource capabilities […]

5 min read

Preparations for Next Moonwalk Simulations Underway (and Underwater)

One of the keys to a sustainable human presence on distant worlds is using local, or in-situ, resources which includes building materials for infrastructure such as habitats, radiation shielding, roads, and rocket launch and landing pads. NASA’s Space Technology Mission Directorate is leveraging its portfolio of programs and industry opportunities to develop in-situ, resource capabilities to help future Moon and Mars explorers build what they need. These technologies have made exciting progress for space applications as well as some impacts right here on Earth.

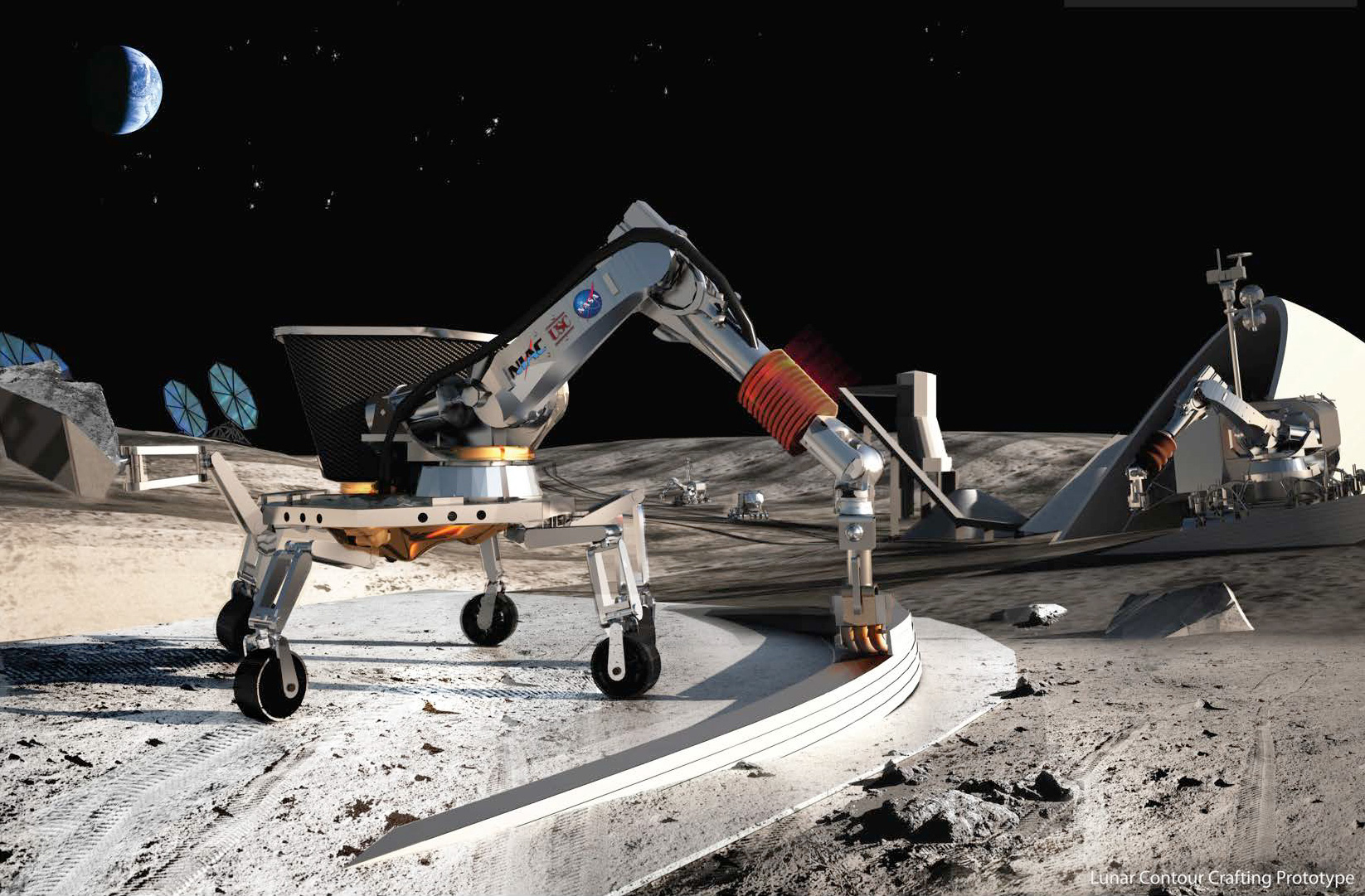

The Moon to Mars Planetary Autonomous Construction Technology (MMPACT) project, funded by NASA’s Game Changing Development program and managed at the agency’s Marshall Space Flight Center in Huntsville, Alabama, is exploring applications of large-scale, robotic 3D printing technology for construction on other planets. It sounds like the stuff of science fiction, but demonstrations using simulated lunar and Martian surface material, known as regolith, show the concept could become reality.

With its partners in industry and academic institutions, MMPACT is developing processing technologies for lunar and Martian construction materials. The binders for these materials, including water, could be extracted from the local regolith to reduce launch mass. The regolith itself is used as the aggregate, or granular material, for these concretes. NASA has evaluated these materials for decades, initially working with large-scale 3D printing pioneer, Dr. Behrokh Khoshnevis, a professor of civil, environmental and astronautical engineering at the University of Southern California in Los Angeles.

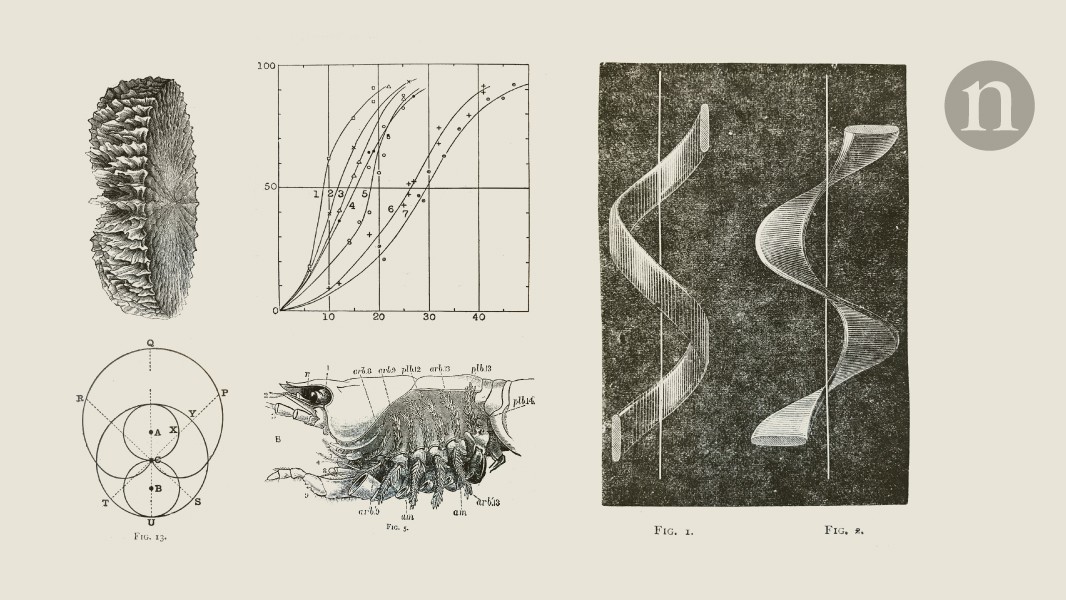

Khoshnevis developed techniques for large-scale extraterrestrial 3D printing under the NASA Innovative Advanced Concepts (NIAC) program. One of these processes is Contour Crafting, in which molten regolith and a binding agent are extruded from a nozzle to create infrastructure layer by layer. The process can be used to autonomously build monolithic structures like radiation shielding and rocket landing pads.

Continuing to work with the NIAC program, Khoshnevis also developed a 3D printing method called selective separation sintering, in which heat and pressure are applied to layers of powder to produce metallic, ceramic, or composite objects which could produce small-scale, more-precise hardware. This energy-efficient technique can be used on planetary surfaces as well as in microgravity environments like space stations to produce items including interlocking tiles and replacement parts.

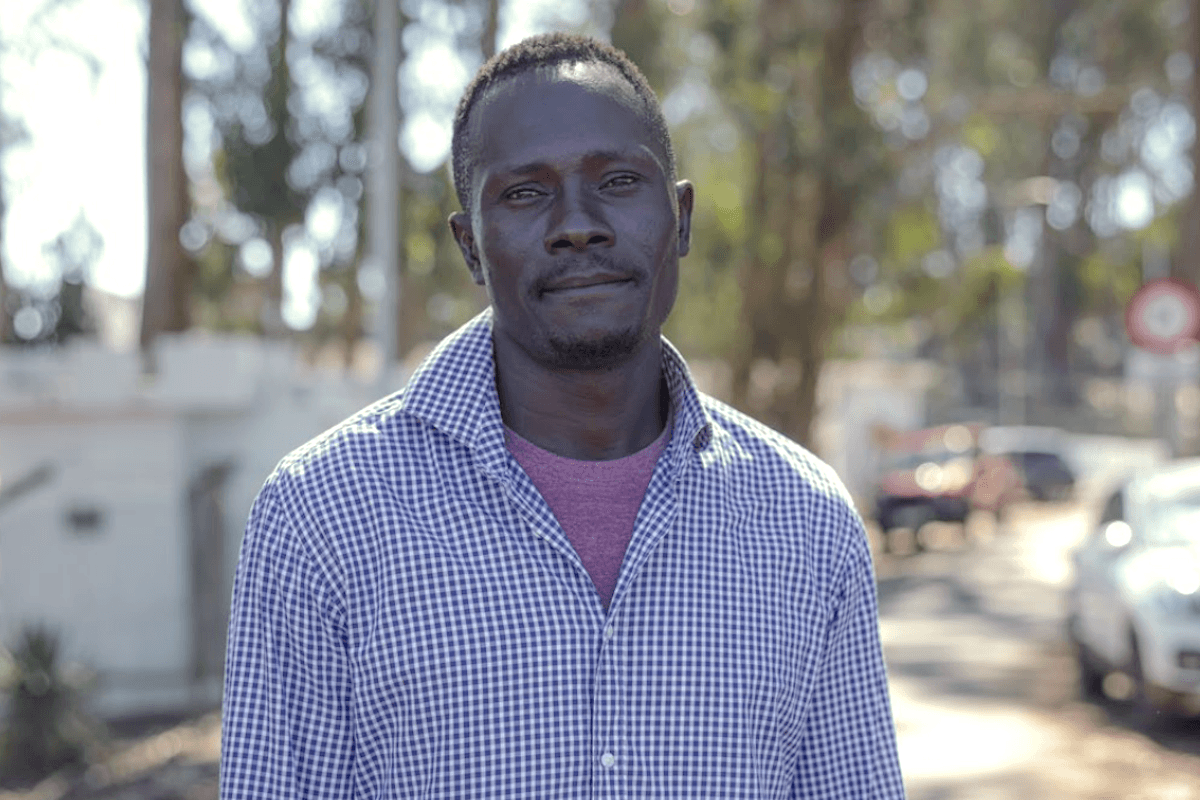

While NASA’s efforts are ultimately aimed at developing technologies capable of building a sustainable human presence on other worlds, Khoshnevis is also setting his sights closer to home. He has created a company called Contour Crafting Corporation that will use 3D printing techniques advanced with NIAC funding to fabricate housing and other infrastructure here on Earth.

Another one of NASA’s partners in additive manufacturing, ICON of Austin, Texas, is doing the same, using 3D printing techniques for home construction on Earth, with robotics, software, and advanced material.

The ICON company was among the participants in NASA’s 3D-Printed Habitat Challenge, which aimed to advance the technology needed to build housing in extraterrestrial environments. In 2021, ICON used its large-scale 3D printing system to build a 1,700 square-foot simulated Martian habitat that includes crew quarters, workstations and common lounge and food preparation areas. This habitat prototype, called Mars Dune Alpha, is part of NASA’s ongoing Crew Health and Performance Exploration Analog, a series of Mars surface mission simulations scheduled through 2026 at NASA’s Johnson Space Center in Houston.

With support from NASA’s Small Business Innovation Research program, ICON is also developing an Olympus construction system, which is designed to use local resources on the Moon and Mars as building materials.

The ICON company uses a robotic 3D printing technique called Laser Vitreous Multi-material Transformation, in which high-powered lasers melt local surface materials, or regolith, that then solidify to form strong, ceramic-like structures. Regolith can similarly be transformed to create infrastructure capable of withstanding environmental hazards like corrosive lunar dust, as well as radiation and temperature extremes.

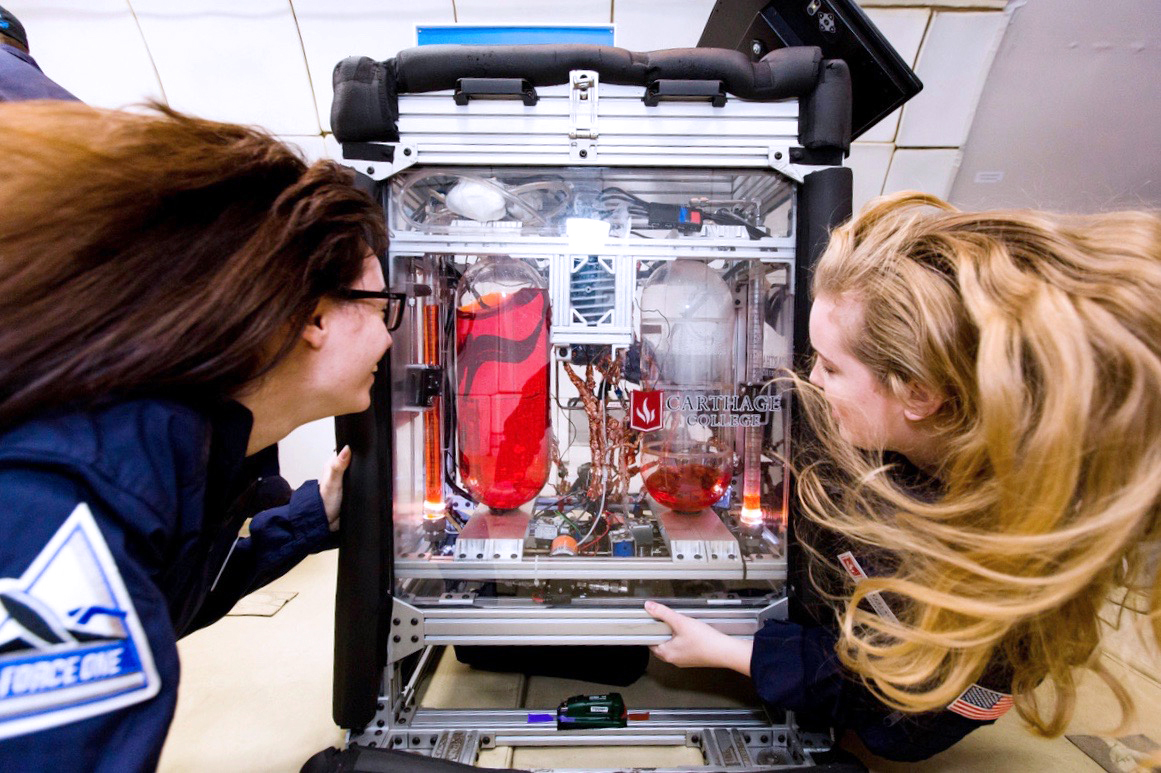

The company is also characterizing the gravity-dependent properties of simulated lunar regolith in an experiment called Duneflow, which flew aboard a Blue Origin reusable suborbital rocket system through NASA’s Flight Opportunities program in February 2025. During that flight test, the vehicle simulated lunar gravity for approximately two minutes, enabling ICON and researchers from NASA to compare the behavior of simulant against real regolith obtained from the Moon during an Apollo mission.

Learn more: https://www.nasa.gov/space-technology-mission-directorate/

![The breaking news round-up: Decagear launches today, Pimax announces new headsets, and more! [APRIL FOOL’S]](https://i0.wp.com/skarredghost.com/wp-content/uploads/2025/03/lawk_glasses_handson.jpg?fit=1366%2C1025&ssl=1)